| Hydraulic Shears Features |

|

|

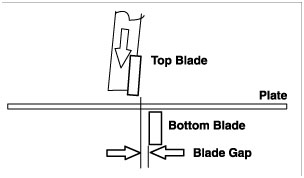

Figure 1:

A guillotine shear has a moving blade that runs on straight slides. The moving blade is almost parallel to the fixed blade during the entire stroke.

|

|

|

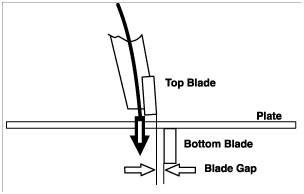

Figure 2:

A shear with a swing beam design has a blade that pivots around a fixed point.

|

Hydraulic Shears are used in many fabricating and sheet metal operations. Before selecting a Hydraulic Shears, several factors must be evaluated, including the type of shear, required capacity, productivity enhancement options, and safety.

Shear type is determined by many factors, including the material length that it can process and the thickness and type of material that it can cut. Hydraulic Shears can be broken down into types by shear design and the drive systems that are used in the design. Two design types are common to power squaring shears: the guillotine and the swing beam.

Shear Design

The guillotine design (see Figure 1, Refer to GUANG BEI QC11 Series) uses a drive system to power the moving blade down and in a position almost parallel to the fixed blade during the entire stroke. Guillotine machines require a gibbing system to keep the blade beams in the proper position as they pass each other.

The swing beam design (see Figure 2 Refer to GUANG BEI QC12 Series) uses one of the drive systems to pivot the moving blade down on roller bearings. This eliminates the need for gibs or ways to keep the blades in proper position as they pass.

Evaluating Shears

One consideration used in evaluating shears is the capacity required for specific jobs. The machine specifications for almost all shears list capacities for mild steel and stainless steel. To compare a fabricator's requirements to those of the machine, the fabricator’s material specifications must be checked against the machine's capacity.

|

|

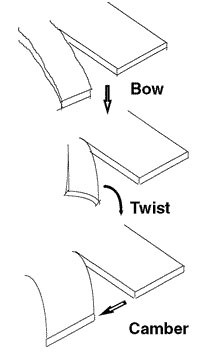

Figure 3:

The problems that commonly influence cut quality are illustrated here. A shear’s rake angle plays an important role in determining cut quality.

|

The rake angle of the blade (the angle of the moving blade as it passes the fixed blade) is important in determining the quality of the cut. Generally, the lower the rake angle, the better is the quality of the cut. Problems with cut quality, such as bow, twist, and camber (see Figure 3), are seen on shorter pieces (up to 4 inches long) that fall behind the shear after they are cut. Machines with lower rake angles require more power than those that have a higher rake.

GUANG BEI QC11 Series guillotine-type shears have a variable rake, a rake angle that can be adjusted to suit the length of the part that is being cut. To evaluate whether this variable rake design is a better option for a fabricator, the type and thickness of the material being cut, the length to be cut, how much of it will fall behind the shear, and the rake angle available for the job must be determined.

For example, if a fixed rake angle has a 1-1/3-inch fixed rake and the adjustable rake machine has a range of 1 to 3 degrees using the 3-degree setting for the 1/4-inch thickness, the fixed rake will produce a better-quality cut on a 3-inch strip. The variable rake machine, on the other hand, may give a better-quality cut on a 1/2-inch strip of 24-gauge material.

Generally, one should not expect a good cut on a strip that is smaller than eight times the material thickness (example: 2-inch strip of 1/4-inch steel). Variable rake machines are generally found in shops with thicker capacity requirements such as 1/2 inch and higher. In the case of these heavier machines, changing the rake angle allows for better cuts on a wide range of thicknesses and types of materials.

|

|